The Once Through Steam Generator is the most common steam source in SAGD facilities. Every operating plant is targeting higher steam quality: at $20 per barrel for bitumen, an extra 1% quality steam equates to an extra $600,000 per year from a single 250 GJ/hr OTSG. A robust control system is needed to keep all of the OTSG passes on the desired steam quality setpoint, and manage the inevitable disturbances from pump swings, feed water temperature changes, and variable fuel quality.

My experience with OTSGs goes back 10 years, and covers spurious firing trips, alarm rationalization, trip management and mitigation of Condensate Induced Water Hammer. Many of the operating incidents in the Steam Generation portion of a SAGD facility can be traced back to the OTSG. This is why I developed a sophisticated simulation for the water side dynamics of an OTSG. This tool provided insight into how the OTSG responded to upsets in operating conditions, and results in a change to the steam generation process. This is analogous to the Shrink and Swell phenomena that is observed in Drum Boilers.

As a result, I have developed a training session to explain the water side dynamics of a typical oilfield Once Through Steam Generation. This training course explains the behaviour of the water side to upsets in operating conditions, and provides tips to increase reliability.

The training sessions are available in a series of YouTube videos:

OTSG Water Side Dynamics: Part 1

Part 1 of 4: Introduction.

OTSG Water Side Dynamics: Part 2

Part 2 of 4: Theory.

OTSG Water Side Dynamics: Part 3

Part 3 of 4: Light-off and response to drop in feed water flow rate.

OTSG Water Side Dynamics: Part 4

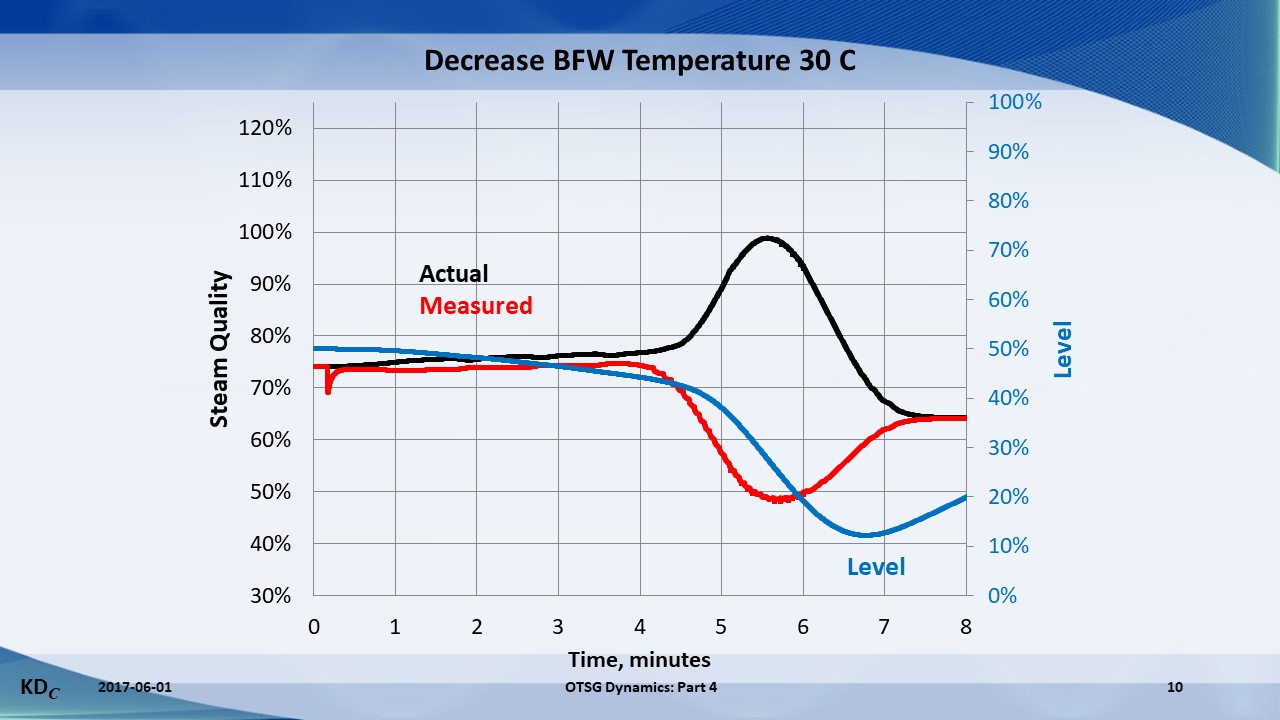

Part 4 of 4: Response to sudden BFW temperature changes.

I used this dynamic simulation to test different strategies for maintaining pass steam quality on setpoint. The result is a custom OTSG control narrative that

- provides optimal control of pass steam quality, and steam header pressure control,

- avoids interaction between the different controllers,

- defines alarm and trip settings that reflects the time needed to reach an unsafe state,

- utilizes the known false readings from the steam quality pass Venturi or flow nozzle.

SAGD facilities typically burn a mixture of natural gas and Produced Gas as fuel. Produced Gas contains significant amounts of non-combustible gas, but may also contain a significant amount of diluent that is flashed from the Free Water Knock-Out or the Vapour Recovery Unit. As a result, the heating value of the fuel gas is often variable, and not measured well. Other industries have developed strategies to manage unmeasured changes in fuel quality, and these methods are implemented in the OTSG control narrative to provide a robust response to fuel upsets.

Implement a robust control strategy today to keep all OTSG passes on setpoint. Be ready for tomorrow when new technology permits operation at 85+% steam quality.